How Shape And A New Connection Technology Contribute To High-Performance HVAC Systems.

Besides improving the energy efficiency of HVAC systems, round ductwork cuts installed costs and adds aesthetic appeal. New connection technology plays a key role. >Download a white paper on spiral duct efficiency (PDF file) .

Get the job done fast and tight with the Complete Seal Spiral Pipe System™

“High performance” has reached buzzword status in the HVAC industry. With energy costs soaring, designers and specifiers are searching for ways to maximize energy efficiency in buildings. The search naturally leads to consideration of HVAC systems, which account for around 40 percent of the energy usage in a typical building. Besides reducing costs, boosting the energy efficiency of HVAC systems helps building owners and operators meet the latest sustainability requirements such as those spelled out in LEED®1, the internationally recognized green-building certification system.

Of course, one way to meet sustainability objectives is to specify more efficient HVAC equipment. So when designing an HVAC system, engineers often focus on the more costly mechanical components such as chillers and air handlers. But there’s another part of the system that has a major impact on performance and efficiency: the ductwork. That’s why today’s smart HVAC system designers and specifiers are carefully considering their ductwork options.

Of course, one way to meet sustainability objectives is to specify more efficient HVAC equipment. So when designing an HVAC system, engineers often focus on the more costly mechanical components such as chillers and air handlers. But there’s another part of the system that has a major impact on performance and efficiency: the ductwork. That’s why today’s smart HVAC system designers and specifiers are carefully considering their ductwork options.

One choice that has much to offer in both new construction and renovation of commercial buildings is spiral ductwork. Advantages of spiral ductwork include efficient air movement and minimal leakage, which can help reduce the energy needs of HVAC systems. Spiral duct is also relatively inexpensive to install and provides an aesthetic asset once in place. Many of these benefits are due at least in part to new self-sealing connection components that come with spiral ductwork made by leading manufacturers.

Shape Improves Airflow

In buildings, spiral ductwork can be a major asset to an HVAC system, which requires power to drive the fan or blower unit that moves air through the ductwork to various locations in the building. If the system fails to deliver the proper airflows, building occupants will turn temperature settings up or down more than should be necessary to meet their comfort needs, which in turn boosts energy use and costs.

Such problems can be lessened by using spiral duct, which produces equal internal pressure and allows even and efficient airflows. Studies have shown that round duct produces less airflow resistance than rectangular duct, which lowers energy use. With the seam entirely on the outside of the pipe, spiral duct also has a smooth interior that minimizes friction losses.

Another key airflow issue concerns pressure. Air leaving an air handler under high pressure drops to lower pressures as it travels through straight ducts, bends and diff users to its destination. In typical spiral duct systems, this pressure drop is less than the one experienced by air flowing through rectangular ductwork. By decreasing the drop in air pressure and increasing airflow efficiency, spiral duct allows the use of smaller, less powerful and less expensive air-moving units.

Another key airflow issue concerns pressure. Air leaving an air handler under high pressure drops to lower pressures as it travels through straight ducts, bends and diff users to its destination. In typical spiral duct systems, this pressure drop is less than the one experienced by air flowing through rectangular ductwork. By decreasing the drop in air pressure and increasing airflow efficiency, spiral duct allows the use of smaller, less powerful and less expensive air-moving units.

Minimized Air Leakage

In addition to airfl ow, air-duct leakage is a major concern of building designers and owners. When ducts leak, HVAC systems require larger and more expensive fans to produce the required airflow. Duct leaks also make fans and other HVAC equipment work harder to maintain the desired building temperatures, increasing energy usage and reducing system efficiency. Often, engineers will specify HVAC systems with larger and more expensive fans to produce the required airfl ow, simply to compensate for duct leakage. An inefficient duct system can be easy to see; if it’s not sealed properly, blowback will build up outside of the ductwork, which is both ineffi cient and unsightly. Other undesirable eff ects of duct leakage include lower indoor air quality and reduced comfort for building occupants.

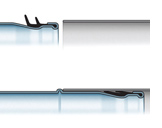

For these reasons, building designers and specifiers strive to produce airtight HVAC systems. By choosing spiral duct, they can meet or exceed the highest industry air-leakage standards—if the right connection and sealing options are also selected. Some leading manufacturers of spiral duct off er special galvanized steel fittings featuring double-legged EPDM rubber gaskets that virtually eliminate leakage at connection points.

The gaskets are mechanically fixed to the fittings with a 180-degree hemmed edge, providing added rigidity to the fittings, which ensures the gaskets will remain secure and create a safe rounded edge for the installer. Unlike conventional sealing alternatives that require the application of duct sealant to the joints, these systems create an airtight connection simply by means of pressure fitting, when the ends of two duct sections are pressed together. Made using lean manufacturing methods and state-of-the-art equipment to maximize efficiency and minimize costs, the fittings meet the requirements of ASHRAE and SMACNA Leakage Class 3.

By minimizing air leakage, these advanced sealing systems reduce the fan energy required to move air downstream through the duct. As a result, they can help building owners pursuing LEED certification optimize for energy performance credits..

Easier And Less Expensive Installation

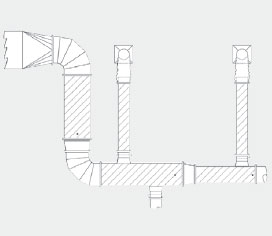

Besides its performance-related features, spiral ductwork off ers other advantages that make it a good choice for HVAC systems. Consider, for example, the positive impact it can have on the installation process. Strong and rigid due to its lockseam construction, spiral duct needs fewer supporting components such

Besides its performance-related features, spiral ductwork off ers other advantages that make it a good choice for HVAC systems. Consider, for example, the positive impact it can have on the installation process. Strong and rigid due to its lockseam construction, spiral duct needs fewer supporting components such

as stiffeners and hangers, cutting both product and labor costs. Spiral duct also requires fewer tools to install—a drill and some screws. In comparison, rectangular duct requires slips and drives, nuts and bolts, gaskets, hammers and snips, as well as fi eld cuts and caulk. The strength of spiral duct also allows it to be made of lighter-gauge, less costly metals than would otherwise be required. As a result, spiral duct can be significantly lighter than rectangular duct, making installation easier—so much easier, in fact, that sometimes it can be installed by just one person rather than two.

In addition, spiral duct normally comes in 10-foot lengths as opposed to fi ve-foot lengths for rectangular duct, reducing the number of connections needed by half to create a duct system and thereby reducing installation time, labor and equipment. Further savings in all these areas are realized by users of advanced self-sealing fittings, which eliminate the need for caulking transverse connections.

Aesthetic Advantages

The lack of messy caulked slip-fit connections also contributes to the aesthetic appeal of gasketed spiral duct. When advanced self-sealing fittings are used, all sealing is internal, so duct seams are smooth and clean. This enhances the attractiveness of exposed spiral duct, which is in favor with designers and architects because it gives buildings a contemporary look.

Today, spiral ductwork is frequently found in modern commercial buildings with open-air designs. These include restaurants, sports facilities, malls, stores and warehouses. In addition, spiral duct is often the choice for public and institutional buildings such as churches, community centers, hospitals and schools.

Conclusion

Over the last half-century, spiral ductwork has taken a commanding market-share lead in Western Europe, which has long been saddled with relatively high energy costs. Though not nearly as common in the U.S., spiral duct is gaining popularity among designers and specifiers struggling to keep up with the latest trends and requirements complicating the job of building construction. Current conditions have increased the need for innovative, high-performance HVAC systems that reduce energy use and costs. Spiral ductwork can give users a significant performance, installation and aesthetic edge, especially when it is paired with the latest self-sealing connection technology.

Learn more about how spiral duct is made: > click here