Recommended Uses:

• DP 1010 may be used to seal metal joints on air duct where a smooth finish is desired.

• DP 1010 may also be used to seal connections on flexible duct or fiberglass duct board.

• DP 1010 is intended for use on duct systems which do not exceed 15 inches water column pressure.

Features And Benefits:

• UL Listed

• Excellent Workability

• Crack and Peel Resistant

• Mildew Resistant

• Excellent Dry Adhesion

• Non-Flammable

• Indoor and Outdoor Usage

• Minimal /Shrinkage

• Sag Resistant

• Excellent Water and U.V. Resistance

• Meets Requirements of NFPA 90A & 90B

• Paintable

Directions For Use:

Surface Preparation: Surfaces should be clean, dry and free of dirt, oil and any foreign matter.

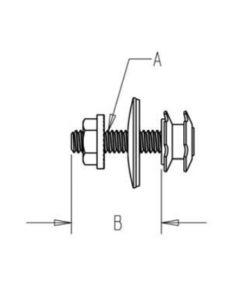

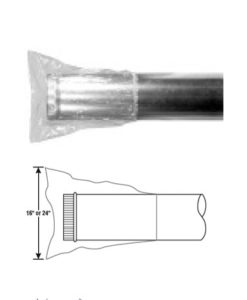

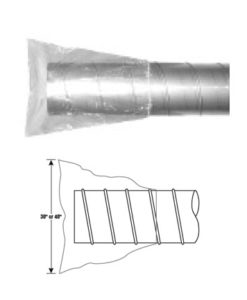

Application: DP 1010 may be applied by brush, trowel, putty knife, caulking gun or pump. DP 1010 should be applied to male and female ends of fittings before being joined. The connected fittings should then be brushed over with an additional cost of DP 1010. Allow a complete cure before testing. Do not thin.

When used in conjunction with UL 181 air duct systems, install mechanical fasteners per manufacturers instructions. Spread DP 1010 at the rate of 80 sq. ft. per gallon (20 mil. wet film thickness). Allow DP 1010 24-48 hours to cure before testing, depending on temperature, humidity and application thickness. Full cure in 72 hours.

Clean up: Warm water and soap while wet.

Technical Data:

Color: Grey

Base: Water

Chemical Family: Synthetic Latex

Solids Content: 75 ± 2%

Viscosity: Approx. 300,000 – 400,000 CPS

Application Temperature: 40°F – 110°F

Service Temperature: -25°F – 200°F

Freeze/Thaw Stability: Through 5 cycles no deterioration (DPTM-20)

Flammability: Non-flammable

Wet or Dry Flash Point: No flash to boiling

Shelf Life: 2 Years (unopened containers)

Cure Time: 24 – 72 hours depending on humidity, temperature and application

Coverage: Dependent on application thickness, 80-100 sq. ft. at 20-30 wet mils.

Packaging: 1/12 gallon tubes, 1 gallon pails, 2 gallon pails, 5 gallon pails, 54 gallon drums

Pressure Classes: Meets all SMACNA pressure classes

Seal Classes: Meets all SMACNA seal classes