> Download Catalog (PDF)

> Download Specs Only (PDF)

> Rectangular Double Wall Duct Product Pages

Specifications for Rectangular Double Wall Duct & Fittings Sheet Metal Connectors, Inc. double wall rectangular duct and fittings are one part of our complete line of HVAC products. Double wall rectangular duct is constructed with TDC end treatments. There are two different types of applications:

• Acoustical double wall duct for noise control

• Thermal double wall duct for temperature control

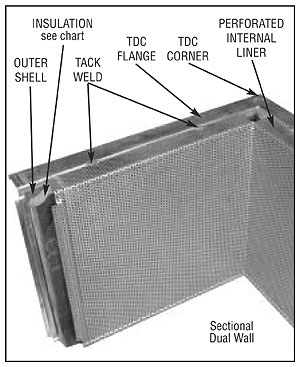

Straight double wall duct comes standard with stiffening beads. Double wall duct is fabricated with either Snap Lock or Pittsburgh longitudinal seams. Sealant is available in the seams upon request. Double wall duct is manufactured completely assembled with TDC corners installed. All sizes shall be listed using inside dimensions.

Acoustical Double Wall

Standard acoustical double wall is for noise control. Constructed of a perforated inner shell surrounded by a layer of insulation and covered by a solid outer shell. The perforated inner shell has 3/32” diameter holes staggered at 3/16” on center for a clear open area of 23%.

Thermal Double Wall

Standard thermal double wall is for temperature control. Constructed of a solid shell surrounded by a layer of insulation and covered by a solid outer shell.

Fittings

Sheet Metal Connectors, Inc. manufactures double wall fittings in most sizes and configurations. Double wall fittings are manufactured on our state of the art fabrication equipment. All double wall fittings are fabricated with stiffening beads on duct sizes 19” wide and larger which have more than 10 square feet of unbraced panel. This requirement is applicable to 20 gauge or less in thickness and 3” W.G. or less. Most double wall fittings are fabricated with Pittsburgh seams. Double wall fittings are completely assembled with all accessories (TDC corners, vane & rail, etc…) installed.

Turning Vane and Rail

SMC manufactures several types of turning vane and E-Z rail. Turning vane and E-Z rail are recommended for square throat elbows and tees. When using turning vane and E-Z rail performance is greatly enhanced in the HVAC duct system. Test data is available upon request.

Maximum Unsupported Vane Length

4” single turning vane ……36” max. length

2” double turning vane …..48” max. length

4” double turning vane …..72” max. length

4” acoustical vane ………..72” max.length

When exceeding maximum vane length, vanes can be installed in sections or a tie rod can be tack welded to the face of the turning vane.

Transverse Joint and Intermediate Reinforcement

SMC manufactures many different types of reinforcement. SMC’s most popular types are as follows: Tie Rod Reinforcement: threaded inserts installed into each end o f thin wall (emt) conduit. These are installed internally at both the joint and/or intermediate duct spacing. R-Angle Reinforcement: roll formed pre-punched angle iron reinforcement. See chart below.

Insulation

Sheet Metal Connectors, Inc. double wall rectangular duct is a dependable, erosion resistant alternative to lined rectangular duct, providing improved protection for insulation exposed to the airstream. In double wall rectangular duct a metal inner liner insures that high airflow velocities cannot separate insulation by pulling away from the duct’s outer wall and creating erosion or airflow problems. Duct liner shall be of the specified materials, thickness, and density of the contractors request. All sizes shall be listed using inside dimensions. Each layer of duct liner shall be attached with a minimum of 90% coverage of adhesive at the liner contact surface area. SMC constructs each piece with an inner shell (perforated or solid) surrounded by a layer of insulation and covered by a solid outer shell. The insulation is used in both acoustical and thermal duct systems.

Sheet Metal Connectors, Inc. double wall rectangular duct is a dependable, erosion resistant alternative to lined rectangular duct, providing improved protection for insulation exposed to the airstream. In double wall rectangular duct a metal inner liner insures that high airflow velocities cannot separate insulation by pulling away from the duct’s outer wall and creating erosion or airflow problems. Duct liner shall be of the specified materials, thickness, and density of the contractors request. All sizes shall be listed using inside dimensions. Each layer of duct liner shall be attached with a minimum of 90% coverage of adhesive at the liner contact surface area. SMC constructs each piece with an inner shell (perforated or solid) surrounded by a layer of insulation and covered by a solid outer shell. The insulation is used in both acoustical and thermal duct systems.

SMC solves air quality problems caused by bacteria and other contaminants that can embed in fibrous materials. These air quality problems can be a health hazard in environments such as schools, hospitals, laboratories, and food or pharmaceutical plants. In cases where additional erosion or contamination protection is desired for such an environment, we can provide a customer specified barrier material (mylar) between the insulation and the perforated liner.

Standard insulation is 1″ thick with 1 1/2 lb. per cubic foot density. See chart below for specifications. Many other thickness’ and densities are available, consult factory.

Specification Compliance

SMC standard insulation meets the requirements of the following codes and specifications:

SMC standard insulation meets the requirements of the following codes and specifications:

NFPA 90A and NFPA 90B

NAIMA Standard AHC-101

ASTM C 1071 Type 1 Replaces HH-I-545B Type 1

Note: SMACNA Testing and Research Institute verified that Sheet Metal Connectors, Inc. shop standards comply with the 1995-2nd edition of the

SMACNA HVAC Duct Construction Standards.