Sheet Metal Connectors, Inc. looks back on history, future for 50th anniversary

For 50 years, the Minneapolis-based Sheet Metal Connectors, Inc. has endeavored to be a trusted partner to HVAC contractors around the country by making products that stand the test of time and integrity. As the company prepares to reach its next major milestone, SMC president and CEO

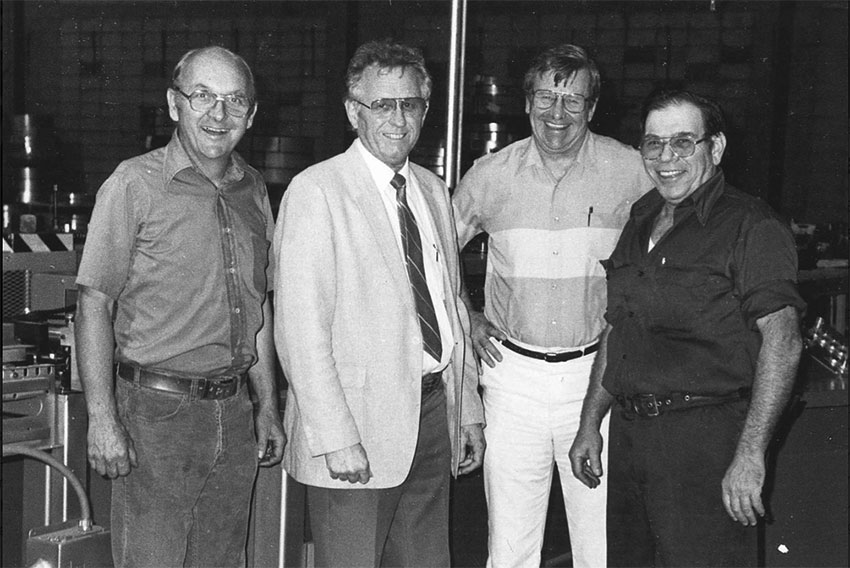

Jim Myers is ready to take that contractor-manufacturer partnership to the next level. When Jerry Myers founded Sheet Metal Connectors, Inc. in 1969, he intended to make the HVAC contractor’s life easier. A half-century and numerous industry-improving patents later, the company’s bottom line is still as simple as that.

“We are working on the next generation right now, doing a lot of training, coaching and development to bring them into the fold. And that’s one of our goals, to keep it family-orientated for generations to come,” says Jim Myers, Jerry’s son. “We are a two-fold business, the regional duct manufacturer and the nationwide component manufacturer.”

A yellow label union shop, Sheet Metal Connectors first began operations in a 3,000 square-foot shop in Minneapolis, Minnesota, manufacturing slips and drive connectors with three employees (Jerry included). “He would be out on the road running down sales, and would come in the building and help run equipment if they had to get an order out. He wore more hats than I could count,” Jim remembers about his father. Now the business has grown to more than 175 employees and three locations with the capacity to supply complete ductwork systems, including, spiral pipe, fittings, rectangular, welded, grease duct, PVS, doublewall duct and a number of other services.

The expansion is a testament to the company’s commitment to quality, Jim says.

“You’ve got to trust that when you do the right thing, and you give a better product, they are going to jump on board. And everybody did,” he says. “Quality is something we take great pride in, and although we might not always have the lowest price, we certainly carry the highest quality.”

As the company prepares for an anniversary celebration later this year, we talked with Jim about longevity in manufacturing and how he plans to get Sheet Metal Connectors to its next 50 years.

What was your path into the family business?

My path was working summers in high school at the shop. It was sweeping doors, loading trucks and packing orders. I went off to college for a couple of years and took the path of sales in the business. As years went on, I entered into inside sales, and later grew into sales manager, then vice president of sales, and currently president.

The company came back under family leadership when you took the reins from Marty Wetzel in 2015. He had been running the company for 15 years. In terms of the business climate, what kind of company were you inheriting?

We had a good operation. We had just made it through some tough years there with the big recession, and we were getting the train back on the tracks, so to speak.

We got rid of a lot of waste in those downtime years, and we went through a lot of lean training for all the employees. So we were already on track to a better way of doing business than what we were. But at the same time, I had I’ve different people who have worked 30-plus years who were retiring. It was a lot of succession planning and getting the new people trained by the people who have been doing it for 30 years. And people who have done a job for 30 years make it look easy. And it’s never as easy as you think it is.

So what I was inheriting was a big change of leadership in many departments. However, we do have a great group of new leaders and a healthy mix of experienced and new employees. We work hard to retain the talented workforce that we have, we promote from within whenever possible, have fully employer paid health care benefits, and matching 401K donations.

With any change in leadership, there is an opportunity to rethink operations and adjust. Did this change set forward some new goals or processes?

Bringing in a new workforce did have its opportunities because folks that have been doing a job for so long can be pretty set in their ways. They are coming from the days of relying on paper versus using computers. They adapted along the way and were using computers but a fresh set of eyes on the processes helps. I let every department take a look at the current procedures and we would go back and review for best practices. And when they had positive changes, I welcomed them.

But you have to go back to my earlier statement. Sometimes the folks that did the job for so long did it that way for a specific reason, so we had to really analyze the changes to make sure we weren’t creating a problem we had already solved.

How has technology played a part in that generational shift of workers?

The two foremen that retired had more than 75 years of experience between them, and they could “feel” where the manpower mwas needed. Well, the new people sometimes didn’t have the feel, and technology has helped. We created new labor tracking and manufacturing software for use within our shop.

With this new technology we have greater efficiencies throughout the operation. We can move people around in minutes by looking at a snapshot of current work now and job progress. Through the years we have bar coded everything so we can now track work throughout our shop. We have invested in automation, custom computer programming, and data transfer.

That sounds like a connection a lot of longtime shops are needing to make when it comes to training the next generation of workers.

It’s kind of funny, when you worked somewhere for so long, I think a lot of the sheet metal people will understand “the feel” for where the manpower is needed. The next generation, they are going to want at their fingertips, on their iPad or their phone. They are going to want to see technology-based information. And that’s where our gains in knowledge came from with a lot of the new folks.

Are there any other ways technology has furthered your business?

About a decade ago we started an online estimating program called PriceDuct. PriceDuct lets the contractors get an instant price and also purchase the ductwork and accessories directly from us. The success of our system comes from the continually updated pricing.

When steel suctuates, it’s really hard for a contractor to go back into their estimating system and change all of the prices from all of the vendors who have a price increase. Our system continually updates its pricing as the market changes, so contractors are always bidding with the most current number. Many contractors, even if they have their own estimating software, will still buy PriceDuct to update their systems.

We are going to continue down the road of integrating with our customers electronically so they can more easily send in quotes, orders, track order process, and even delivery.

On the door how has automation played a role in operations?

We have been automating for decades with auto feeders, robotics and things like this. We see that is a necessity for the HVAC market. Some of our biggest competitors are still the contractors that feel that they can make it themselves, and our goal is to help them understand the amount of waste we eliminate and the efficiencies we bring as a manufacturer with our people doing it all day, every day.

Now I am a big fan of labor, and what I mean by that is the world needs people, and we are going to have hands-on in the construction side for years to come. But, on the manufacturing side, we will see more and more automation coming at us. And if you’re not keeping up with automation, people will see you in their rear view mirror very quickly.

So what you’re saying is we shouldn’t be scared of automation. Automation and manpower can happily coexist?

Automation allows us to use our labor force in a more effective way. We are taking them out of repetitive jobs and we are putting them where they can effectively use their skills, which allows us to be more efficient and turn out a higher volume of material. We’ve never let a person go in our company’s history because of automation.

It gives us more business, which allows us to grow in other areas. Our employees are what make us a successful company, their hard work, dedication, and ideas are what makes Sheet Metal Connectors great.

Looking at Sheet Metal Connectors history, would you say you’ve always been an early adopter in the industry?

I would say we are leaders in the industry. Sheet Metal Connectors has always been looking to make eld labor as efficient as possible, and create a more energy efficient HVAC system.

We’ve gotten six different patents on products through the years. The last product, the Super Heto (Stamped High-Efficiency Takeoff), was a patent we designed to increase the airflow on takeoff collars. Complete Seal is another product line that we have introduced that allows contractors to install an airtight spiral duct system without the use of sealant.

That falls into labor savings, right?

There are cases that show pre-fabrication can have 15-20 percent overall labor savings. The trick for us is to show the contractors the benefit of shifting some of their field allocated labor to the manufacturer. With the labor shortage in many areas of the county, we feel that the pre-assembly in the shop will help to make job sites much more efficient.

That really hits home to Sheet Metal Connector’s goal in being a partner to the contractor.

Every job is different, so we must adapt to meet the customer’s needs. Whether it’s pre-fabrication, logistics or the type of ductwork that should be used. We want to partner with them and make sure that each job gets an individual focus and runs as smoothly as possible.

On the job site, things are going a lot faster, timelines are shortened and you have many trades working side-by-side with compressed schedules. We really have to think about jobs before they start so that we can be the most efficient partners in both the manufacturing process and help their installation go smoothly.

We want to be their fab shop. That’s really our goal. So whether they need one product, or nfull pre-fabrication of the job, we want to be the go-to for all of their needs.

What is most important to you as you move into the next 50 years?

At the end of the day, I feel the number one thing we have to do is earn our customers trust every day. It is the trust that we are going to do the right thing, that we are going to be there when you are in a pinch, the trust that we will communicate if we have a question, or see a mistake. Integrity is what my Dad built this company on and it is still at the core of everything we do today.

Article By Emell Adolphus

Editor-in-chief of Snips Magazine